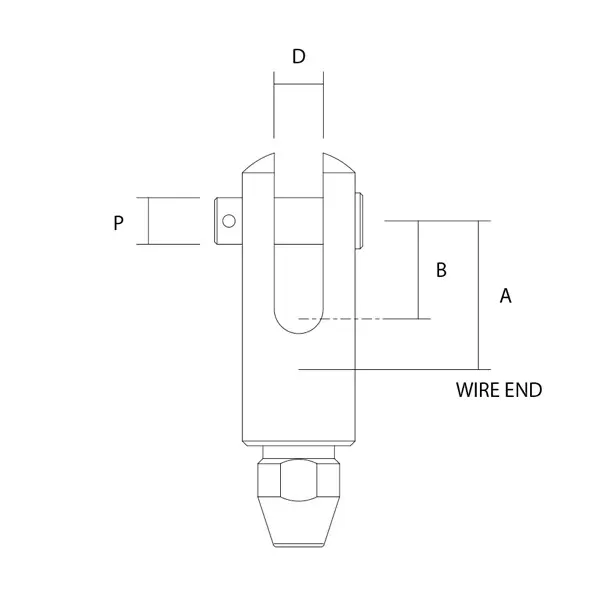

Description

Over 48 years since its inception, Sta-Lok self-fit terminals are used around the world and have gained worldwide recognition for high quality and reliability.

For use with the right hand and left hand lay 1×19, 7×19, 7×7 and compacted strand stainless steel wire rope from 3mm – 26mm (1/8” – 1”).

The Sta-Lok self-fit terminal will work under constant loading and variable shock loading. The termination is stronger than the rated breaking load of the wire rope. In all situations, the Sta-Lok terminal has proven to be totally reliable and re-usable*.

*Just a new wedge is required

- Assemble on-site, easy to install with simple hand tools

- No pre-measurement required

- A different wedge is required for 1×19, 7 strands and compacted strand wire rope

- All our wedges are laser marked for easy identification and selection

- Guaranteed stronger than wire rope